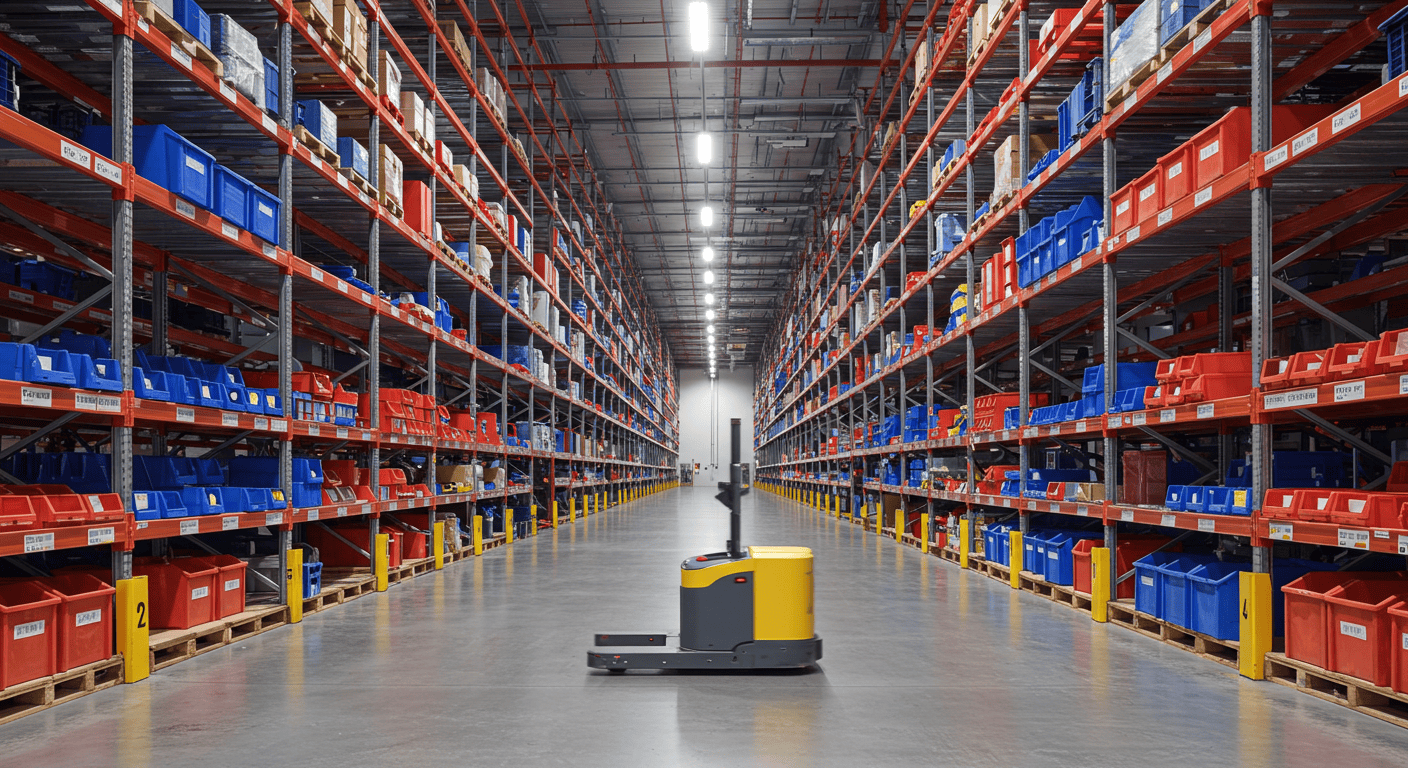

Optimizing MRO Supply for a Manufacturing Leader

Industry: Heavy Manufacturing

Overview

A major manufacturing client faced production delays and high costs due to an inefficient MRO supply chain. Pinnacle implemented a full-scale Vendor-Managed Inventory (VMI) system to automate reordering, consolidate suppliers, and provide real-time visibility.

Key Deliverables

- Full Supply Chain Analysis

- Vendor-Managed Inventory (VMI) System

- Strategic Supplier Consolidation

- Standardized PPE Program

- Real-Time Performance Reporting

The Challenge

A leading heavy manufacturing firm was experiencing production slowdowns due to stockouts of critical MRO (Maintenance, Repair, and Operations) parts. Their decentralized procurement process led to excessive inventory costs for some items and critical shortages of others, with no clear visibility into their supply chain.

Our Strategic Solution

Pinnacle implemented a comprehensive Vendor-Managed Inventory (VMI) system. We began with a full audit of their MRO needs and consolidated their supplier base. By integrating our VMI software, we established automated reorder points and provided the client with a real-time dashboard for complete inventory visibility. This included a streamlined supply program for essential Personal Protective Equipment (PPE).

The Outcome

The client achieved a 20% reduction in overall MRO inventory costs while increasing parts availability to 99.8%, virtually eliminating stockout-related downtime. The new system streamlined the procurement process, reduced administrative overhead, and ensured 100% compliance with new safety standards through the managed PPE program.

Project Gallery

.jpg)